Posted 07-10-16

I am David ’Morty’ Mortimer.

I

worked

for

Auto-Wrappers

for

over

42

years

(1968

to

2010).

I

started

as

an

apprentice

on

19/08/68

at

8.00

in

the

morning

and

the

very

first

person

to

speak

to

me

was

George

Wiggett,

who

said

‘don’t

look

so

worried

lad’.

Apprenticeship

There

were

9

apprentices

in

my

first

year

of

which

we

spent

in

the

training

school

,

Bob

Howorth

and

Johnny

Wright

were

our

training

officers.

the

traing

school

was

situated

next

to

the

plating

shop.

The

1968

apprentices

were

Peter

Blyth,

Dick

Bull,

David

‘Jake’

Johnson,

Alan

Catchpole,

Keith

Sadler,

Peter

Watts,

Roger

Hadden,

Steve

Dickenson

and

myself.

The

first

year

was

taken

up

by

making

a

lot

of

our

tools

EG

vices,

scrapers,

screwdrivers,

height

gauge,

G

clamps

and

main

more.

I

remember

Jake

taking

about

12

attempts

to

screw

cut

one

8

inch

screw

length

for

the

vice

we

made.

After

the

first

year

we

were

all

let

lose

into

the

factory.

One

job

we

had

to

do

whist

apprentices

was

to

go

round

the

factory,

after

the

morning

tea

break

with

the

lunch

menu

to

find

out what people wanted to eat, so the canteen could prepare the lunches for the one hour dinner break.

As

I

was

doing

the

technical

course

at

Norwich

City

College,

i

was

required

to

do

work

experience

i

was

to

go

into

the

planning

office

for

3

months,

followed

with

3

months

working

in

the

stores

before

then

going

into

assembly

shop

for

6

months.

The

next

three

and

half

years

were

spent

working

through

all

the

departments

like

details,

turret

and

horizontal

mills,

centre

lathe

and

6

months

with

my

"adopted

dad",

Ivan

Mortimer

on

the

capstan

lathe.

I

finished

the

last

6

months

of

my

5

year

apprenticeship

working on inspection within the machine shop.

Drawing

Office

Years

After

the

first

5

years,

I

applied

and

got

the

job

in

the

drawing

office

as

a

detail

draughtsman.

In

these

days

in

1973

all

the

design

and

detail

drawings

were

all

hand

drawn

on

drawing

boards.

I

worked

with

section

leader

Jeff

Bloomfield

and

fellow

detailer

Kelly

Knott

on

the

Mark

1

verso

flow

machines,

One

year

we

issued

83

sold

machines

to

the

production

department

to

make

and

deliver

to

customers

(the

hey

day

of

flow

wrapping).

The

Mk1

versoflow

did

not

change

very

much

during

the

70’s

and

80’s

but

the

infeed

systems

to

feed

in

the

product

to

the

machines

did.

The

main

work

in

the

Drawing

office

was

to

design

and

detail

infeeds

and

new

size

parts.

From

the

Mk1

evolved

the

4

Sided

Seal

Machine,

also

a

top

seal

variety,

and

a

biscuit

on

edge

machine

(BOE).

I

did

a

lot

of

work

on

the

4

sided

seal

machines,

normally

for

packed

medical

products

and

spent

time

at

"Smith

and

Nephew"

in

Hull

and

"Johnson

and

Johnson"

at

Gargrave.We

also

had

many

good

times

out

of

the

office,

We

had

drawing

office

fishing

days

on

Surlingham

and

Ramworth

broads.

I

remember

that

Roy

Cook

had

a

theory

on

how

to

catch

fish...

he

said

"The

bigger

the

bait,

the

bigger

the

fish"

So

he

used

a

big

earth

worm

to

try

and

catch

a

big

fish

and

to

hopefully

to

win

the

match,

only

to

end

up

catching

a

2

inch

long

Bullhead

fish,

which

we

said

"the

only reason tha he had caught the tiddler, was because the worm had actually wrapped itself around the fish like a python".

In

the

80’s

we

also

had

some

good

times

in

the

Drawing

Office

with

a

lot

of

tricks

and

windup’s

going

on

by

Roy

Cook,

Mike

Harvey, Ernie Rose, Julian Woods and of course... myself.Some of the following happened:

1

-

Terry

Lappen,

the

technical

writer

owned

a

camper

van

so

we

sent

him

a

fake

letter

telling

him

he

would

have

to

pay

poll

tax on his camper van as it was his second home. It took him weeks to find out that it was a windup.

2

-

We

put

Mike

Harvey’s

house

up

for

sale

whilst

he

was

on

holiday,

Roy

Cook

managed

to

borrow

a

very

large

"For

Sale

Bachelor

flats"

sign,

and

put

it

in

his

front

garden

whilst

he

was

away

on

holiday.

The

best

thing

was

a

local

councillor

called

round to Mike’s to see if he was really selling his house.

3 - The lads put my car in the ‘cars for sale’ in the Eastern Evening News.

4

-

We

made

Graham

Conway

a

“Do

it

yourself

operation

kit”

out

of

samples

we

were

wrapping

in

the

factory,

we

gave

it

to

him

whilst

he

was

in

hospital.

The

best

bit

was

that

he

got

told

off

by

the

hospital

for

having

unofficial

scalpels,

syringes

and

sewing

thread on the ward.

5

-

We

sent

Jeremy

Howlett

a

fake

letter

from

the

ambulance

service

for

‘frequent

user

insurance’

after

he

had

been

knocked

of

his

bike

a

couple

of

times

and

landed

up

in

hospital.

The

letter

stated

if

he

did

not

take

out

the

insurance,

the

ambulance

would not turn out the next time he was knocked off his bike. It took him 10 hours to find out it was a windup.

6

-

Mike

Harvey

and

Roy

Cook

doctored

my

packet

of

Golden

Wonder

plain

crisps,

by

refilling

it

with

cheese

and

onion

crisps

and then re-sealing the pack with the hand sealer end crimps. But I got the last laugh…

by complaining to Golden Wonder and they sent me 12 free packets of plain crisps. Thanks lads.

7

–

Jeremy

Howlett

crashed

his

motor

bike

one

night

so

the

next

day

we

made

him

a

Yamaha

rebuild

kit

from

old

cams,

brackets,

electrical

wire

and

odd

parts.

This

was

all

put

in

a

large

box

and

put

on

his

drawing

board.

On

his

return

to

work

the

next

afternoon

the

box

was

thrown

across

the

office

by

a

very

angry

Jeremy.

This

cleared

the

office

for

about

15

min

before

he

calmed down.

In

the

drawing

office

we

had

a

‘Take

the

P’

box

in

which

we

had

to

put

in

5p

very

time

we

took

the

P

out

of

each

other.

Over

the

year

we

would

collect

enough

money

to

go

out

to

dinner.

The

main

‘P’

takers

were

Mike

Harvey,

Ernie

Rose,

Graham

Conway,

Roy

Cooke,

John

Marlee,

Jeremy

Howlett,

Julian

Woods,

Chris

Rayner

and

Carl

Brooke,

This

went

on

for

many

years.

Meanwhile,

the

flow

wrappers

were

evolving

in

the

80’s

with

the

introduction

of

the

Mk3

machine

with

the

end

and

bottom

crimps

being

driven

though

gearboxes

but

was

not

a

roaring

success,

Then

came

the

Mk5

flow

wrapper,

which

was

design

like

a

panther

tank

being

made

out

of

welded

thick

plates,

This

machine

was

mainly

mechanical

with

a

large

open

back

on

it

for

easy

maintenance.

All

the

standard

and

special

infeeds

would

fit

onto

this

machine

and

even

a

Biscuit

On

Edge

version

was

designed.

In

the

late

80’s

computer

aided

design

(CAD)

was

introduced

into

the

Drawing

Office,

I

had

to

go

to

Barnsley

and

Nottingham

to

test

two

systems

of

CAD

to

see

which

one

was

the

best

for

Autowrappers.

We

chose

HP-ME10

and

4

units

were

put

into

the

drawing

office.

we

spent

the

next

6

months

drawing

all

the

standard

parts

onto

the

CAD

system,

Then

the

technical

director

at

the

time

did

not

like

or

understand

the

system

and

shut

it

down.

The

sets

were

transfered

down

the

road

to

the

Europack

Factory at Beccles.

We

also

had

some

sad

times,

I

remember

Reggie

Suffolk

the

chief

draughtsman

having

a

heart

attack

and

died

in

the

office

in

the

mid

70’s.

Peter

Flander

(Poppy)

died

from

a

brain

tumour,

as

did

Brian

Daynes

a

few

years

later.

Mike

Knights

died

from

a

heart attack and poor Roy Cooke had a rear cancer and died a week before his first child was born.

Aftersales Years

In

the

90s

I

transferred

into

the

sales

department

to

become

part

of

the

Spares

and

Ancillary

section.

This

position

formed,

as

this

area

of

the

business

had

been

hit

by

redundancy

the

year

earlier.

In

the

section

was

Roger

Knight,

Barbara

Myhill

and

myself.

Steven

Joy

handed

the

rains

over

to

Paul

Holmes

who

became

the

department

manger.Through

the

90,s

and

00’s

the

departments

turnover

increased

as

we

offered

a

full

solution

to

the

customers

requirements

for

ancillary

equipment

and

spare

parts.

I

travelled

to

many

customers

factories,

quoted

for

the

parts

required,

designed

and

issued

the

change

parts,

chased

through manufacturing, shipped to customer and briefed the engineers to fit the equipment on site.

In

2005

GEI

sold

the

business

to

Bradman

Lake,

and

a

bit

later

we

left

Whiffler

road

and

moved

to

a

larger

new

factory

in

Old

Hall

Rd.

But

we

did

not

know

it

at

the

time

but

we

were

not

going

to

stay

there

very

long,

as

the

old

Bradman

Lake

was

suffering

financial

problems.17

Oct

2007

was

a

very

stressful

day.

I

was

working

in

Toronto

Canada

with

Glyn

Sparkes

and

was

to

fly

down

to

the

Bradman

Lake

offices

in

Charlotte

at

6am

in

the

morning.

after

boarding

the

plane

we

found

it

had

an

electrical

fault

on

push

back.

so

the

plane

returned

to

the

gate,

and

I

got

off

the

plane.

I

now

had

a

6

hour

wait

for

the

next

flight,

so

I

went

into

a

café

to

have

breakfast,

which

I

paid

for

on

the

company

card.

I

then

went

back

to

the

same

café

at

about

9.00

and

again

tried

to

pay

on

the

card.

The

card

was

denied

in

that

time

the

company

had

gone

bust.

So

there

i

was...

stuck

with

no

money

and

a

dud

phone,

as

the

one

I

had

been

given

didn’t

work

in

Canada.

I

finally

got

onto

the

12.00

flight

and

arrived

in

Charlotte

mid

afternoon

with

no

one

to

pick

me

up

as

no

one

knew

where

I

was,

as

I

was

6

hours

late

and

no

phone

to

tell

anyone

had

happened.

After

the

company

when

bust

it

was

sold

to

the

Langley

group

(

the

current

owners

)

they

decided

that

new

factory

overheads

were

too

expensive,

so

they

moved

the

business

to

the

Europack

site

in

Beccles,

18

miles

away

where

it

still

is.

The

only

apprentices

from

the

1968

intake

left

working

at

this

time

were

Dick

Bull,

Jake

Johnson

and

myself.

I

travelled

to

the

new

site

for

just

over

2

years

everyday

on

the

bus

but

eventually

left

AW

(Bradman

Lake)

on

19th

April 2010.

I

spent

42

years

working

at

Auto-Wrappers,

I

made

many

good

friends

and

colleagues

and

when

you

leave

after

that

amount

of

time,

it’s

the

people

you

miss

(even

Smarty).

I

am

now

working

part

time

at

Snetterton

race

track

as

a

medic

which

is

fantastic, as I now go motor racing nearly very day.

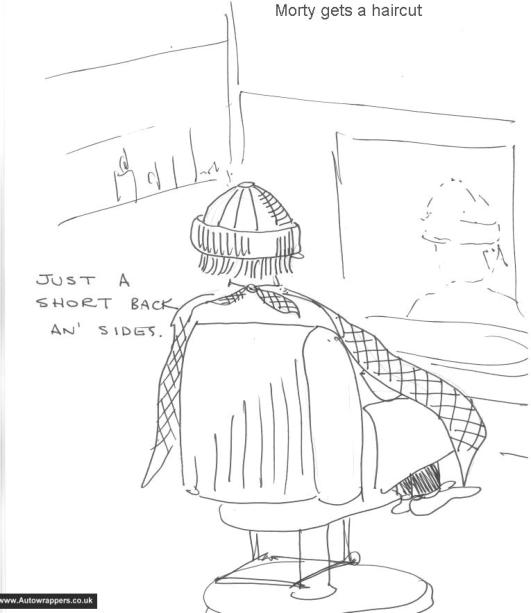

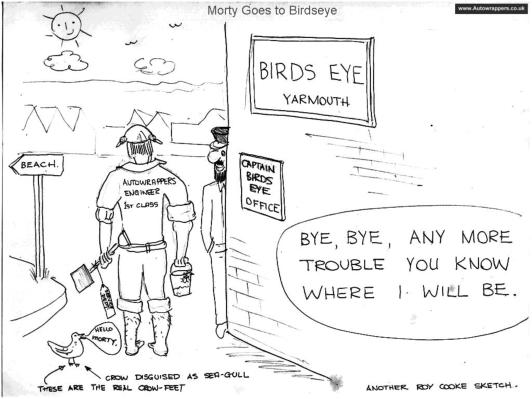

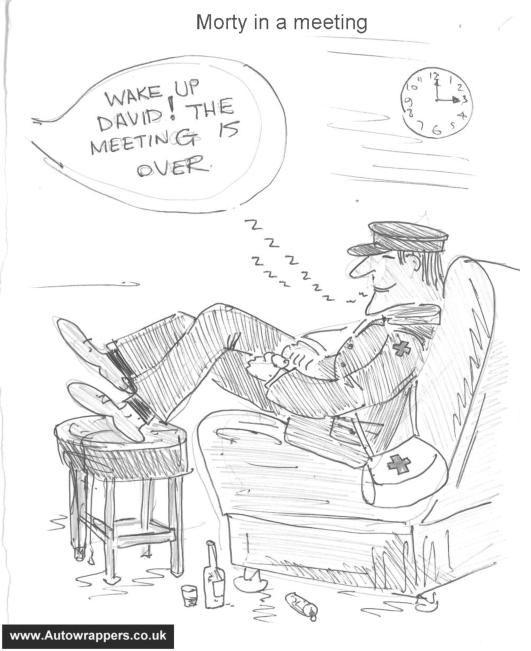

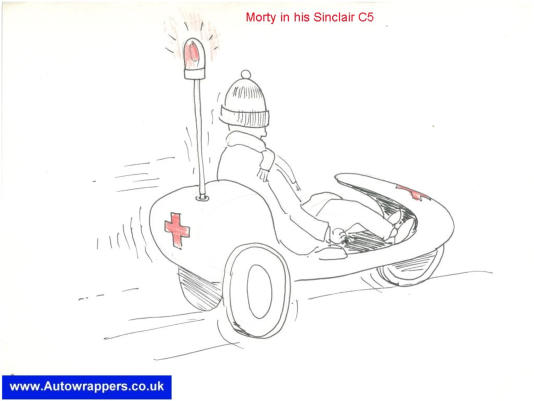

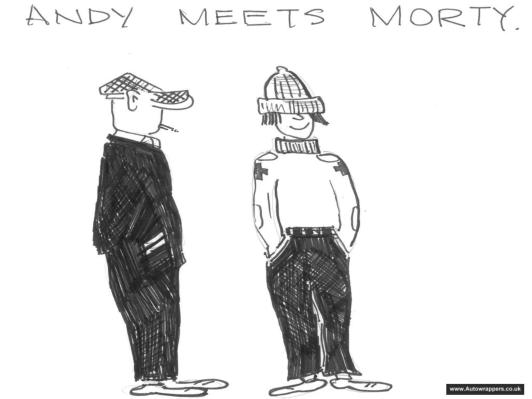

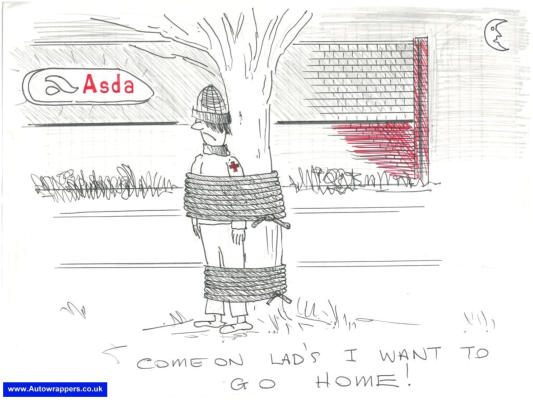

Below are some drawings of Morty by Ernie Rose...

Morty's History

David ’Morty’ Mortimer.